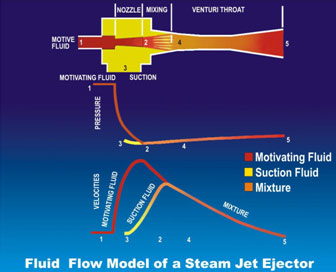

The steam jet ejectors are pumps that mix or compress different fluids.

They have no moving parts and operate by the action of one high pressure stream entraining steam ,air and other vapors (or liquids) at a lower pressure into the moving stream and there by removing them from the process system at an intermediate pressure higher than the suction pressure but many times lower than the motive steam pressure.

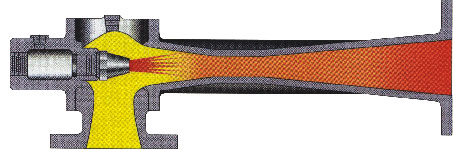

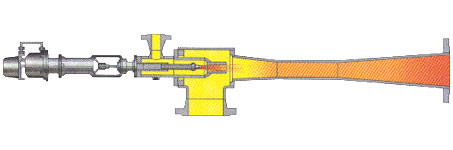

The main components of the steam jet ejectors are: the nozzle, the suction and mixing chamber, the diffuser.

Steam jet Ejectors have the following features which make them good choices for continuously producing economical vacuum conditions:

1. They handle wet, dry or corrosive vapor mixtures.

2. They develop any reasonable vacuum needed for industrial & other operations.

3. All sizes are available to match any small or large capacity requirements.

4. Their efficiency is good.

5. They have no moving parts, hence maintenance is low, and operation is fairly constant when corrosion is not a factor.

6. Stable operation within design range.

7. Installation costs relatively low when compared to mechanical vacuum pumps. Space requirements small.

8. Simple operation and maintenance.