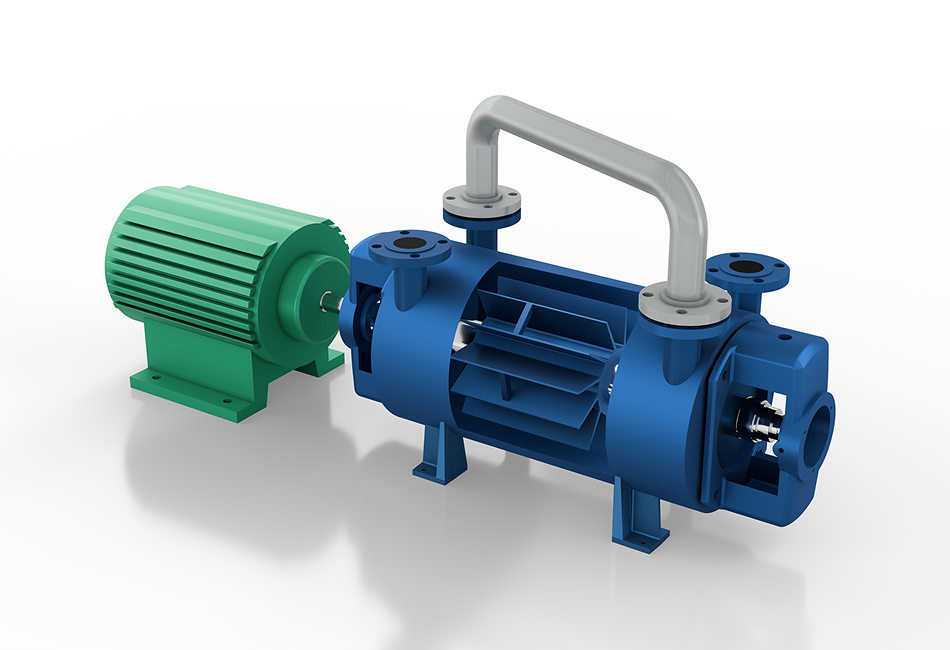

Single/Double Stage Liquid

Ring Vacuum Pumps

Mazda’s next-generation two-stage liquid ring vacuum pumps deliver superior efficiency, high reliability, and long-term energy savings.

Engineered with advanced design, they minimize operating costs while maximizing performance across diverse industrial applications.