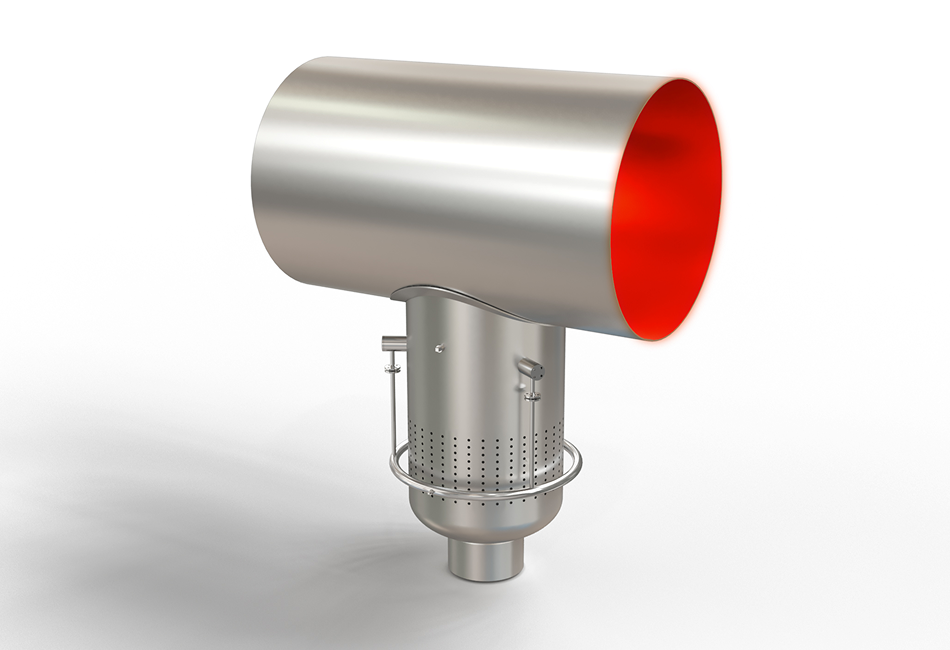

Dump Tubes

Engineered to manage steam expansion and cooling during turbine bypass or load variations.

Mazda Dump Tubes ensure safe, efficient, and cost-effective discharge into condensers or turbine exhausts.

Engineered to manage steam expansion and cooling during turbine bypass or load variations.

Mazda Dump Tubes ensure safe, efficient, and cost-effective discharge into condensers or turbine exhausts.

Designed to minimize bypass valve size and reduce system cost.

Custom-built for smooth steam flow, noise reduction, and reliable integration with condensers.

Product Details

Mazda’s Dump Tubes are precision-engineered components that optimize the discharge of steam into condensers or turbine exhausts during bypass operations, start-ups, or sudden load variations. They provide the final stage of pressure reduction, allowing steam to expand and cool before entering the condenser. By reducing the size and requirements of turbine bypass valves and associated piping, Dump Tubes deliver both technical and cost-saving advantages. Each unit is tailor-made to meet installation requirements, ensuring compatibility, reliability, and long service life under demanding operating conditions.

Dump Tubes are fitted into the condenser inlet duct or turbine exhaust, where they act as the final stage of steam pressure reduction. Strategically drilled holes in the tube direct steam flow either across 90° sectors (in condenser installations) or 360° around the circumference (in turbine exhaust installations). This controlled expansion prevents turbulence, reduces noise, and ensures uniform steam distribution. In air-cooled or water-cooled applications, spray water devices can be integrated for precise steam temperature management using automated control algorithms.

In multi-effect evaporators, capturing and reusing waste steam after the final effect

Steam recovery in drying and processing stages

Energy recycling in evaporation and concentration processes

In multi-effect evaporators, capturing and reusing waste steam after the final effect

Copyright © 2025 Mazda Ltd. | All Rights Reserved

Website Design And Developed By CorpTeaser

Our team is available to provide professional support and will respond promptly to any inquiries or assistance you need.

Enquire Now