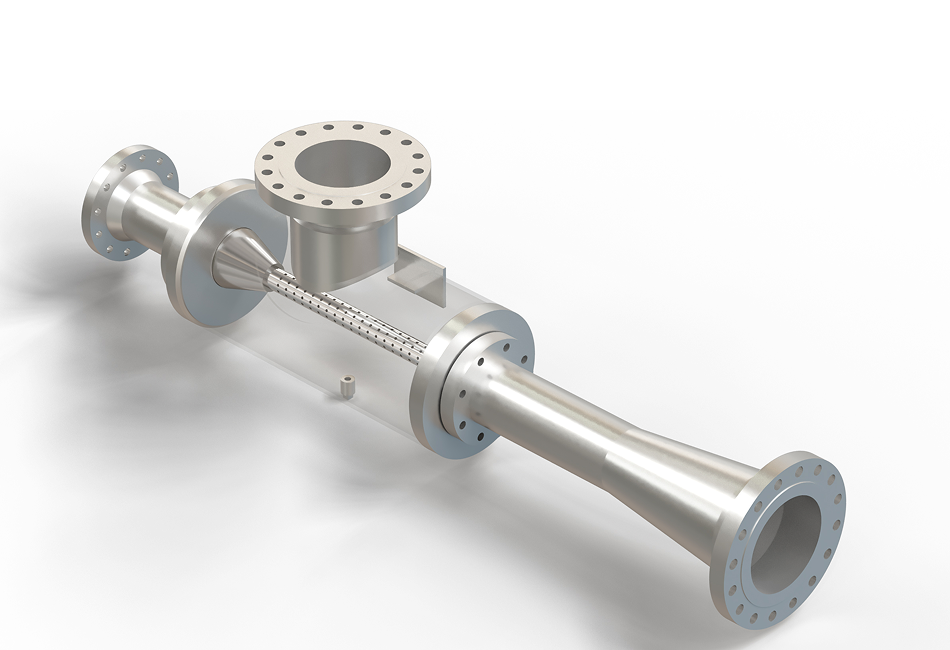

Water Heater with holes (Orifice)

Mazda Steam Jet Heaters provide a reliable and efficient method to heat liquids through direct injection of steam.

With no moving parts and simple construction, they deliver safe, trouble-free, and cost-effective heating solutions.