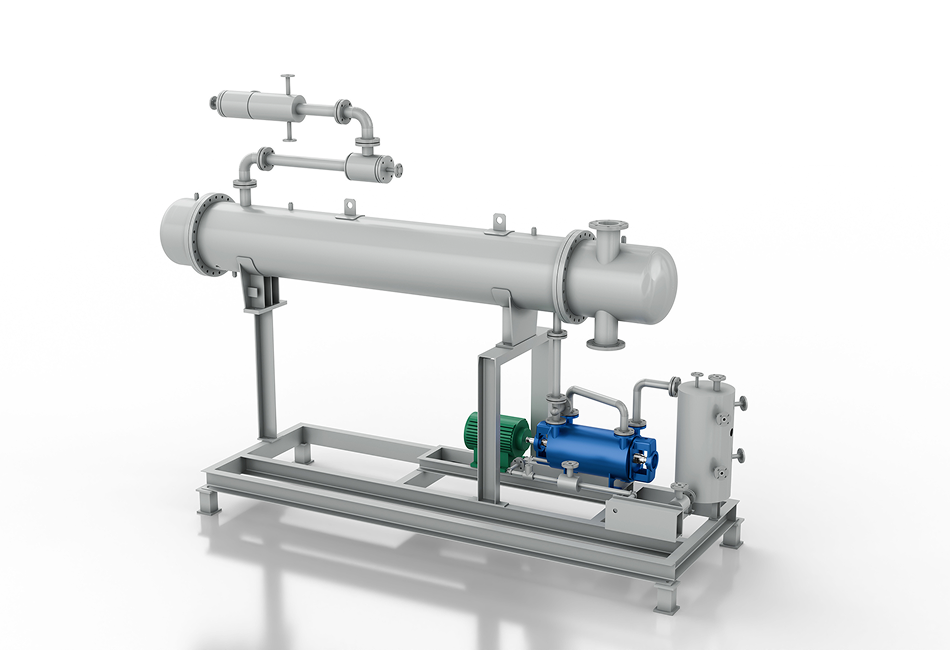

Rotajector Ejector

Mazda’s Rotajector delivers the best of both worlds — the simplicity of a steam jet ejector and the efficiency of a rotating vacuum system.

Designed for demanding industrial applications, it ensures high reliability, low maintenance, and superior energy savings.