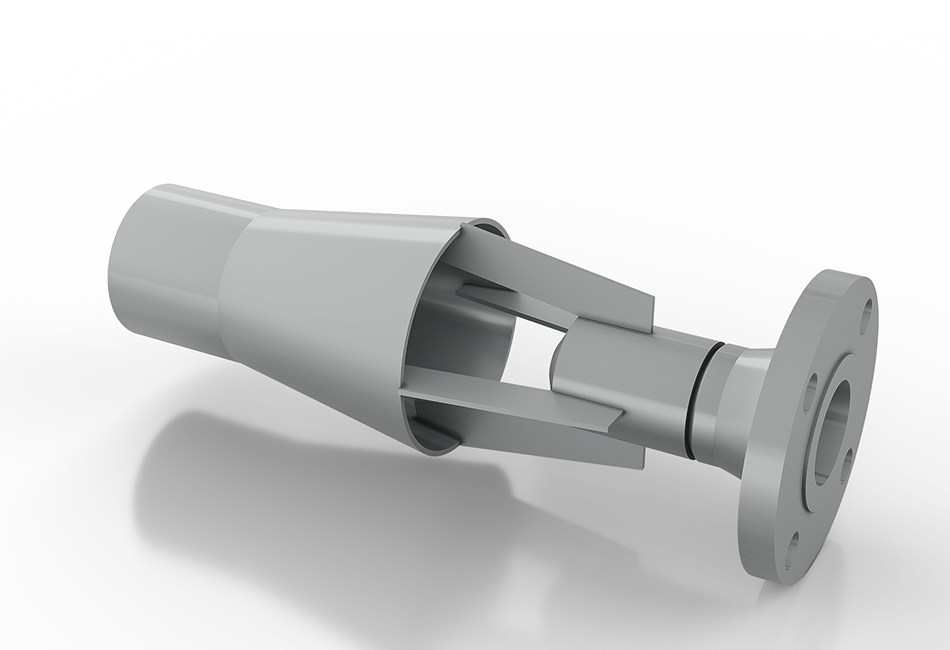

Steam Jet Liquid Heaters and Mixers

Efficient, compact, and highly reliable, Mazda’s Steam Jet Heaters and Mixers provide a seamless way to heat and mix liquids.

Designed for durability and ease of use, they ensure consistent performance with minimal maintenance.